The International Code Council Evaluation Service has granted official AC509 certification to MAPEI Corporation’s Planitop 3D construction ink/mortar, according to a press release.

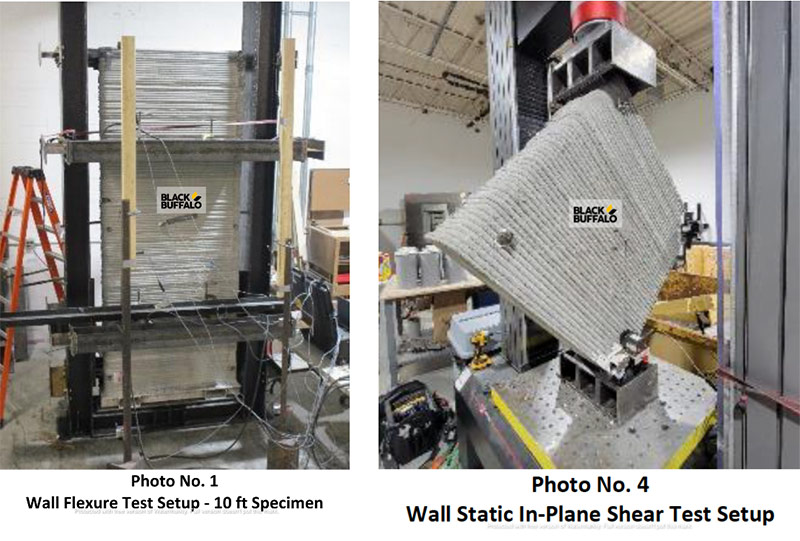

The certification came after extensive testing of the concrete-based ink/mortar. AC509 code requirements for “bearing, nonbearing, and shear walls up to 40′ in height” were found to be met by both Planitop 3D and partner company Black Buffalo 3D printing technology, according to MAPEI.

“It underscores the fact that our team, along with Black Buffalo 3D, was able to create the best 3D ink/mortar in the world. MAPEI is known globally as the leading manufacturer of building materials for the construction industry,” commented Luigi Di Geso, president and chief executive officer, MAPEI Corporation.

The exclusive AC509 cement-based construction ink/mortar has been created after extensive research, testing, and evaluation by outside and internal material scientists at MAPEI, Black Buffalo 3D, and a number of outside labs, including Intertek.

The completion of the AC509 certification process for MAPEI’s Planitop 3D represents the final step in a lengthy approvals process. The verification process included testing and verifications at the material, machine, and printed wall levels, adhering to the criteria of the ICC-ES AC509 standard for 3D printed walls.

“Planitop 3D will unlock the true potential of 3D construction printing by providing contractors and builders with internationally accepted certification that their projects will be strong and durable,” added Di Geso.

On-demand and on-site 3D printing is now a legitimate coded technology, thanks to Planitop 3D’s ICC-ES AC509 code approval. Large-scale 3D construction printers and ink/mortar will change how the world addresses issues such as affordable housing, emergency shelters, and resilient infrastructure.