![]() Becker Marine Systems has been working on solutions to make dynamic positioning (DP) and auto-pilot (AP) systems more efficient. According to Becker, in order to improve maneuverability under computerized DP + AP support systems there is a need for timely, direct or indirect measurement of rudder forces, which allows the generated lift and resistance to be determined. For this purpose, a method for measuring the rudder forces is necessary, the company said, which is able to determine rudder force vectors by direction and amount. By using current rudder force as input parameters for a DP or AP system, maneuvering hysteresis can be eliminated or significantly reduced.

Becker Marine Systems has been working on solutions to make dynamic positioning (DP) and auto-pilot (AP) systems more efficient. According to Becker, in order to improve maneuverability under computerized DP + AP support systems there is a need for timely, direct or indirect measurement of rudder forces, which allows the generated lift and resistance to be determined. For this purpose, a method for measuring the rudder forces is necessary, the company said, which is able to determine rudder force vectors by direction and amount. By using current rudder force as input parameters for a DP or AP system, maneuvering hysteresis can be eliminated or significantly reduced.

In a first approach, a rudder force measurement arrangement has been applied on full spade rudders. An installation on the rudder trunk and the rudder shaft measures forces by sensors or strain gauges. Compared to a state-of-the-art maneuvering arrangements, an interface calculates the appropriate rudder angle for maneuveering forces as inputs from the steering gear. It also will process the measured forces, adjust the rudder angle and provide feedback to the DP system about the actual forces.

Becker has developed a force measurement arrangement for full spade rudders, capable of determining rudder lift, drag and an interface for processing the sensor signal and transferring force data to the DP system. The interface provides standard protocol (NMEA 0183) as well as analogue signal output. The receiving system requires the capability of processing real time force signals, predicting force development on corresponding actuation from the current thrust-rudder force condition.

Becker said that the improved performance in maneuverability will lead to more reliable and safer operation in DP, fewer maneuvering motions with lower fuel consumption and reduced emission of CO2, NOX, SOX.

Signal processing

The control unit calculates each force component from four sensors signals and transform these into rudder coordinates for the appropriate components that can be used by the vessel’s coordinate system. Rudder force information is sent via the network and can be received by any navigation control system connected to it. To maintain the integrity of these systems the received data is used to refine the results from standard operation mode. Data validation is performed by defined allowable deviation from navigation system results, as well as by BIMS internally, considering all input values and checking for plausibility.

Rudder Force Display

BIMS is able to display rudder forces at any place with network access. Three display modes are available: 1) Display totals for lateral force and drag values. This mode can also be used to indicate thatthe rudder force is low and only little response is expected under current conditions. 2) Display a graph showing force application over time in chronological sequence. This mode makes it possible to visualize forces and to adjust the optimal rudder angle and RPMs. This ensures optimal rudder performance, especially in emergency situtions. 3) Indicate the optimal rudder angle for a specific speed and rudder force actually applied in relation to maximum force.

BIMS is able to display rudder forces at any place with network access. Three display modes are available: 1) Display totals for lateral force and drag values. This mode can also be used to indicate thatthe rudder force is low and only little response is expected under current conditions. 2) Display a graph showing force application over time in chronological sequence. This mode makes it possible to visualize forces and to adjust the optimal rudder angle and RPMs. This ensures optimal rudder performance, especially in emergency situtions. 3) Indicate the optimal rudder angle for a specific speed and rudder force actually applied in relation to maximum force.

Economic Effects

Decreasing power needs and frequenty of control operations of all components in the propulsion system along with increased maneuverability in AP mode results in fuel savings of approx. 2-3 % with a corresponding reduction in emissions, according to Becker. For the DP mode, the expected savings will be significantly higher due to operation characteristics, the company claimed, but added that this cannot be accurately quantified, because of what it called unsteady disturbances. In standby operation of one of two main engines savings of approximately 50 percent in fuel and emissions can be expected in DP mode, it said. Considering that more vessels will be operating in Emission Controlled Areas (ECA) in the future, savings can increase even further. A subsequent reduction in wear on the bearings will also result in an extension of maintenance intervals from the current two years to an interval corresponding to the class required for five-year dry-dockings.

System Advantages

Becker lists the system advantages to include: Reliable and safe dynamic positioning/maneuvering operations; Less rudder motion in DP and AP mode; Energy savings through improved efficiency; Elimination of aft tunnel thrusters on a case-by-case basis; Emission reduction; “Quieter” rudder system; Reduced manoeuvring response times; Significantly less rudder motion; and Reduced waste and maintenance costs.

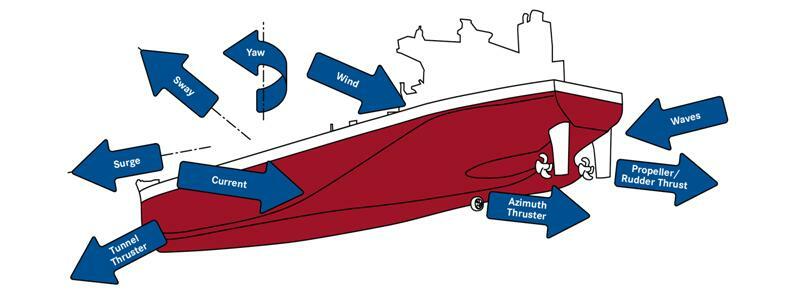

Computerised manoeuvring operations today

Modern DP and AP systems utilise a variety of input signals to maintain course or position from positioning reference sensors, combined with wind sensors, motion sensors, gyro compasses, GPS data, etc. These data are processed by an IT system to allow the course or drift to be predicted and to calculate countermeasures controlling the actuators in the vessel’s propulsion system. Input data and processing is of high quality, but only reflects the vessel’s motion response. Inertia causes a massive decrease in the strength of these control signals, which may not meet or provide sufficient quality for maneuvering, according to Becker . For rudder-propeller arrangements relatively high corrections are applied to rudder angles, resulting in high rudder forces. The vessel turns more than necessary for the predicted course correction, resulting in a similar counteraction in the opposite direction. This effect results inhysteresis, or rudder flipping, causing the steering gear to work continuously and more or less strong fluctuations around a set course or position.